The Portrait Of A Norwegian Plumber

What is your full name? Which is your occupation?

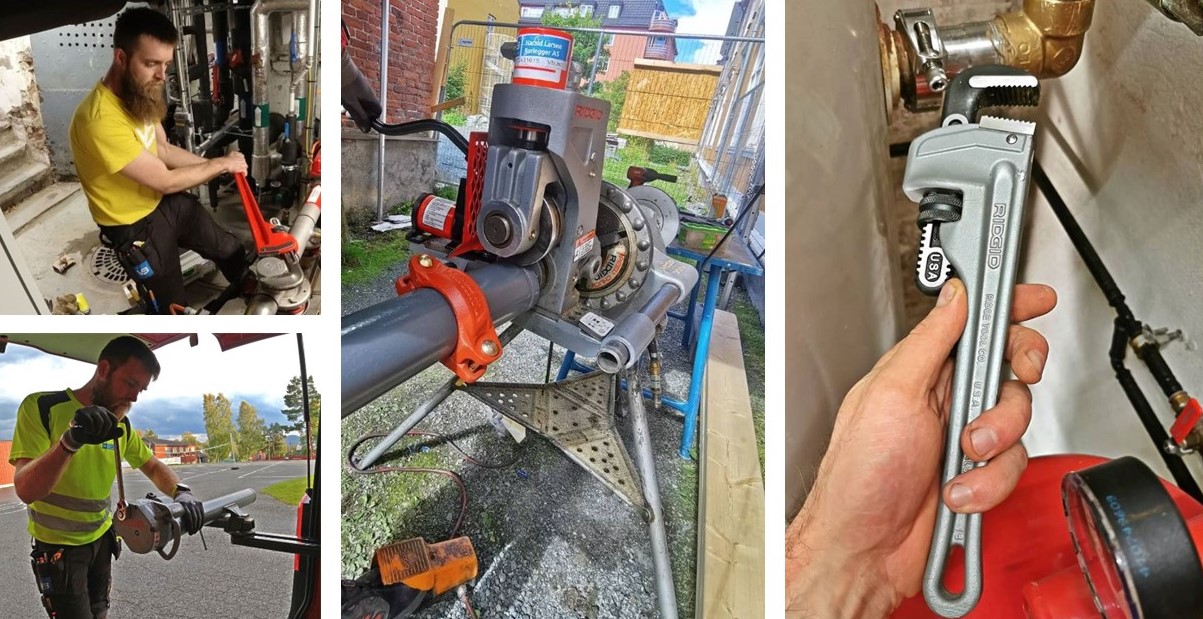

My name is Jostein Larsen and I live in Norway. I am a proud plumber and together with my brother I own and run a plumbing company that our father started in 1988.

When and how did you start your career in trades?

As my father is also a plumber, growing up I got to spend a lot of time with him at work. I have always enjoyed manual working and brainstorming on solutions was something that kept me challenged all the time. There weren't many professions, other than plumbing, that made me interested.

Tell us about your everyday work. What kind of projects are you working on? Which are the tools and technologies you use for connecting tubing and piping?

I usually work on larger projects such as schools, kindergartens, nursing homes, city halls, multi-purpose halls and so on. In terms of projects, I usually work on sprinklers, HVAC and sanitary projects. Currently, I am working on the final stages of a handball hall with three floors with car parking underneath. I did a lot of sprinkler work here, which involves the use of both the 918 Roll Groover and the HC-300 Hole Cutter. The joining methods here have been with Victaulic couplings and parts. We use grooving both for sprinklers (DN40>) and on the larger dimensions of the heating system (DN65>).

What’s the best part of working in trades? What about the most challenging one?

I really like the variety of the working days and also the fact that I can take some small service jobs in between. The most challenging thing is always time. It takes a lot of time to run a plumbing business, while also having a family and going to school part-time to become an engineer.

How and when did you discover RIDGID?

RIDGID has always been in the company since my father bought his first RIDGID 700 Threading Machine, long before I became a plumber. So I have been surrounded by RIDGID tools from an early age.

Which is your RIDGID favourite tool and why?

My favourite RIDGID tool is not the biggest nor the strongest, but it is solid, light and very good to use. It is my RIDGID 812 Aluminium Straight Pipe Wrench.

We’ve seen you use the 918 Roll Groover on a lot of jobs. Tell us a few details about it and the jobs you use it for.

Yes, as I mentioned earlier, the RIDGID 918 Roll Groover is one of the tools I use the most, especially on steel pipes in diameter DN40 to DN150, on both sprinklers and HVAC jobs.

I like it very much, it is solidly built, does the groove job quickly and is also gentler on shoulders and wrists. We also have its little brother 915, which we use to make grooves on pipes in, for example, old heating systems we are rebuilding.

We do not use welding because we do not want to carry out heat work indoors. With grooving, we avoid the risk of fire, as we don’t create any heat.

What about the HC-300 Hole Cutter?

I mostly use it for sprinklers and heating systems, on pipe diameters from DN 40 to DN 150.

For the project I am currently working on now, it has been in use every day since June. I use it in prefab or just to drill a hole on a pipe that is already installed. When you split the machine in two, it is easy to attach it at right angles to the pipe. I wouldn’t prefer a regular drill with a hole saw over the HC-300 Hole Cutter. I don't use thread oil when drilling holes, I believe there will be less spillage without the use of oil. All in all, I think the HC-300 is a fantastic hole saw machine, which I should have gotten before.

STAY IN TOUCH WITH US, SUBSCRIBE TO OUR MONTHLY NEWSLETTER AND DISCOVER OUR SOCIAL MEDIA CHANNELS: HERE.