The Portrait Of An Irish Welder

July 19, 2023

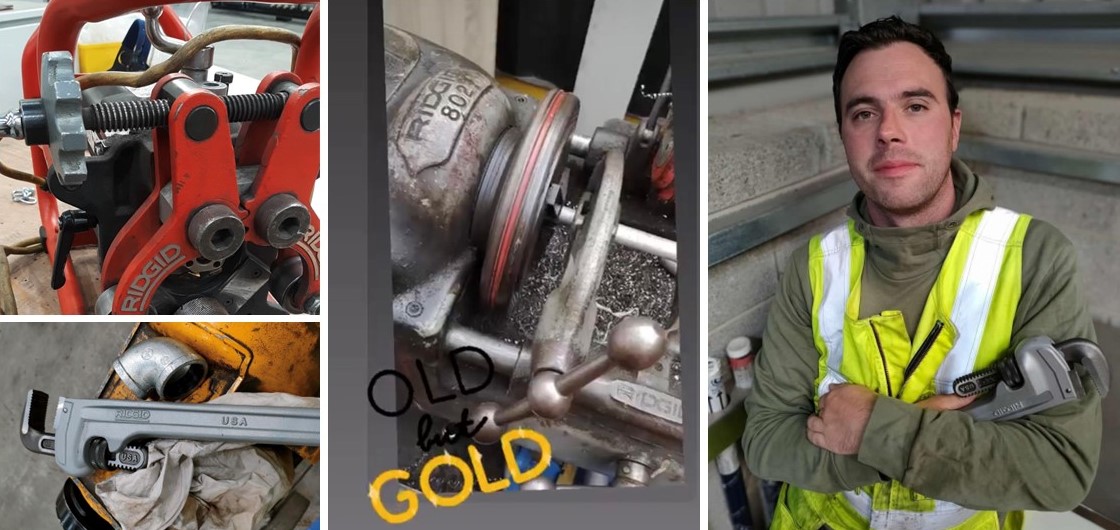

Johnny Burke is a third-generation metal worker in Ireland. He is passionate about trades, but also about tools, technology and innovation in the tools business. One of Johnny's dreams and hopes is to pass his trade legacy to the next generation.

Let's discover together more details about Johnny! Happy reading!

It's very simple to use and easy to change the cutter tooling. They are also bulletproof; they can take knocks and never give bother.

Let's discover together more details about Johnny! Happy reading!

What's your name and job role?

My name is Johnny Burke and I am a proud Welder in Ireland.When and how did you start your career in trades?

I'm a third-generation metal worker so it's pretty much in my blood. I started to work in this field because of my father. Growing up I was pretty much his shadow and I just loved his work and the smell of welding and hot metal.Tell us about your everyday work – what kind of projects are you working on; which tools and technologies do you use?

Luckily for me, every working day is different and brings its own challenges. From welding up pipe spools to swinging on wrenches, this variety keeps work exciting and keeps you engaged. Working with different materials tests your knowledge and keeps you up to date on new technologies: from carbon pipes to stainless steel, copper and plastic, there is a wide range to be keeping an eye on.What’s the best part of working in trades? What about the most challenging one?

Trades are always evolving and I think this is one of the best parts of what I do. There is always new stuff to learn, new tools to make your life easier and make your scope of working wider. The most challenging part is represented by deadlines, which are getting tighter and tighter nowadays. You still have to take pride in your work and do the work to the best of your abilities, so shortcuts are NOT an option.How and when did you discover RIDGID?

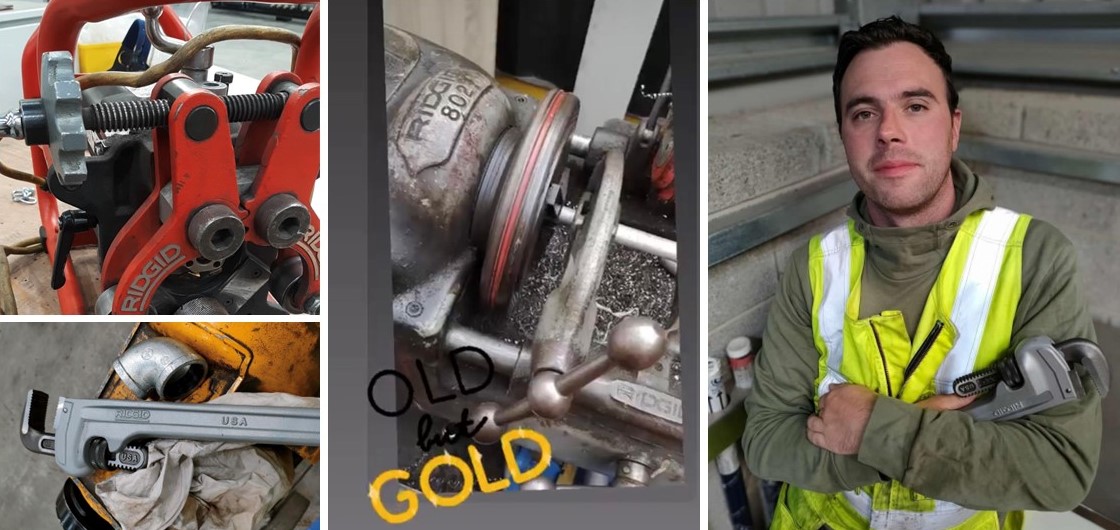

There are a couple of brands I've inherited from my father. When it comes to piping tools, RIDGID is one of these brands. Never let him down, never let me down!Which is your favourite RIDGID tool and why?

It’s hard to pick, probably because from threading to beveling I rely on a lot of RIDGID bits daily. If I had to pick, it has to be the Heavy-Duty Pipe Wrench. It's in my hand daily!Let’s talk a bit about the RIDGID B-500 Pipe Beveller. What type of application do you use it for? (pipe material, diameter) What is your opinion on this tool?

The RIDGID B-500 is a game-changer! On standard size pipe 6" & 8" it takes a 15/20 minute job and knocks it out 3/4 minutes and with a far more consistent bevel. It also reduces operator fatigue and increases productivity. You’re spending less time beveling and prepping and more time putting pipes together.It's very simple to use and easy to change the cutter tooling. They are also bulletproof; they can take knocks and never give bother.

When do you think about RIDGID, which are the first things that pop into your mind?

When I hear RIDGID, I just think of quality and the iconic red wrench! When I hear piping, I think RIDGID. You can just see someone turning that Red Pipe Wrench!! Also the smell of the cutting fluid from the threading machine... That’s RIDGID to me!We turned 100 years this year. Do you have a message for us?

Keep doing what you’re doing! You guys have been doing it right for generations! I hope to follow the tradition and pass down a red pipe wrench to my daughter and son.